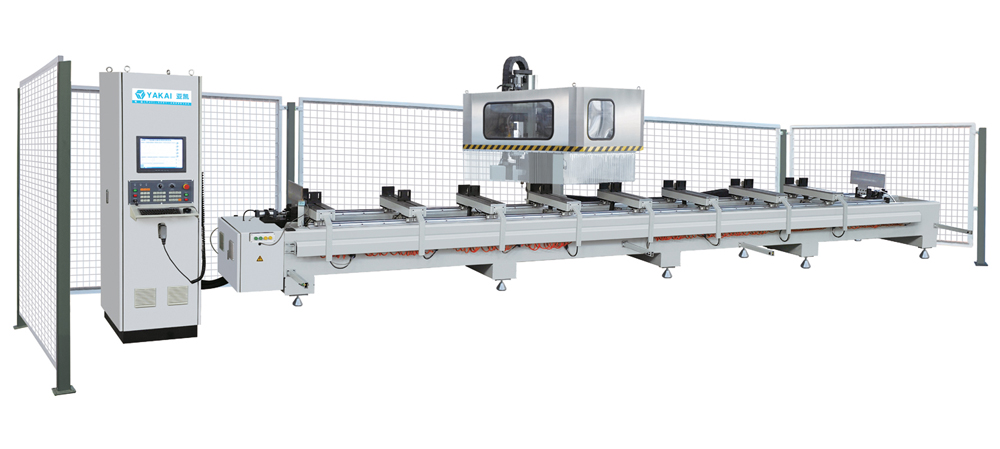

● This machine is designed for processing launder, taping, milling, and mounting hole, locking hole and other slots for diversified curtain walls and aluminum doors and windows.

● It adopts high-speed electric principal axis, which is imported form Italy. It is extremely efficient and can swing in ±90°.

● It adopts high quality computer control system, which is used in industry area specially. The system has favorable user manipulate interface program in graphics mode and processing interface. This processing interface can show related dates directly.

● It adopt high-quality servo-motor, roller linear guide pair to insure the machine runs with high precision.

● The cutter storage supply 12 cutter positions, the cutter can change quickly and automatically.

● With half-close safeguard device to insure the personal safety of the operator.

● The position of clamping device can put freely.

Spindle power:9kw

Spindle speed:0-24000rpm

Air pressure:0.5-0.6MPa

X-axis speed:50m/min

Y-axis speed:30m/min

Z-axis speed:20m/min

Cutter max length:130mm

Cutter handle model:ISO30

Cutter library:8 position

Type of clamping:Pneumatic clamps (8 group)

Cutting range:1200×300×6000mm

Overall dimension:11300×2500×2500mm

ZA-CNC-7000High-speed Four-axis CNC Machining Center can be used with the following equipment to compose Aluminum Door and Window Machine production line.